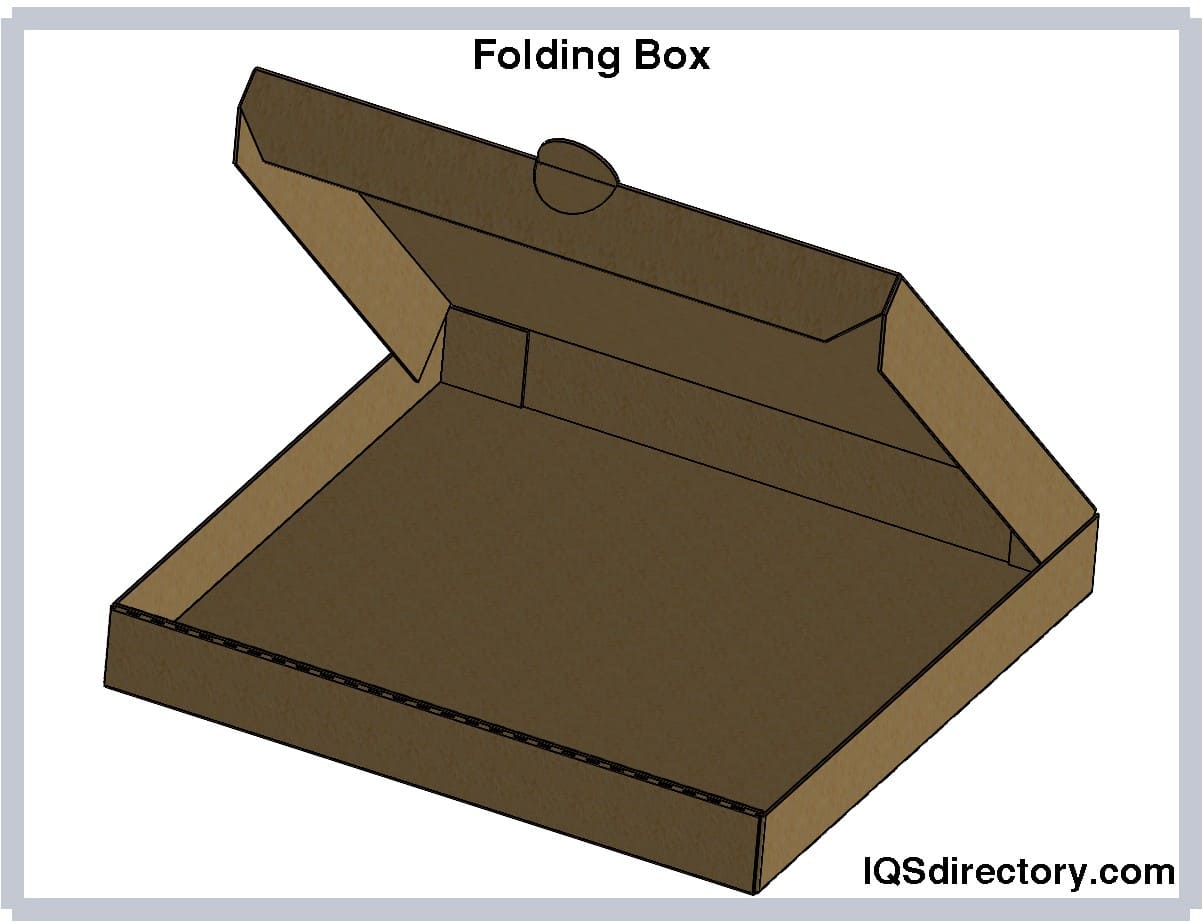

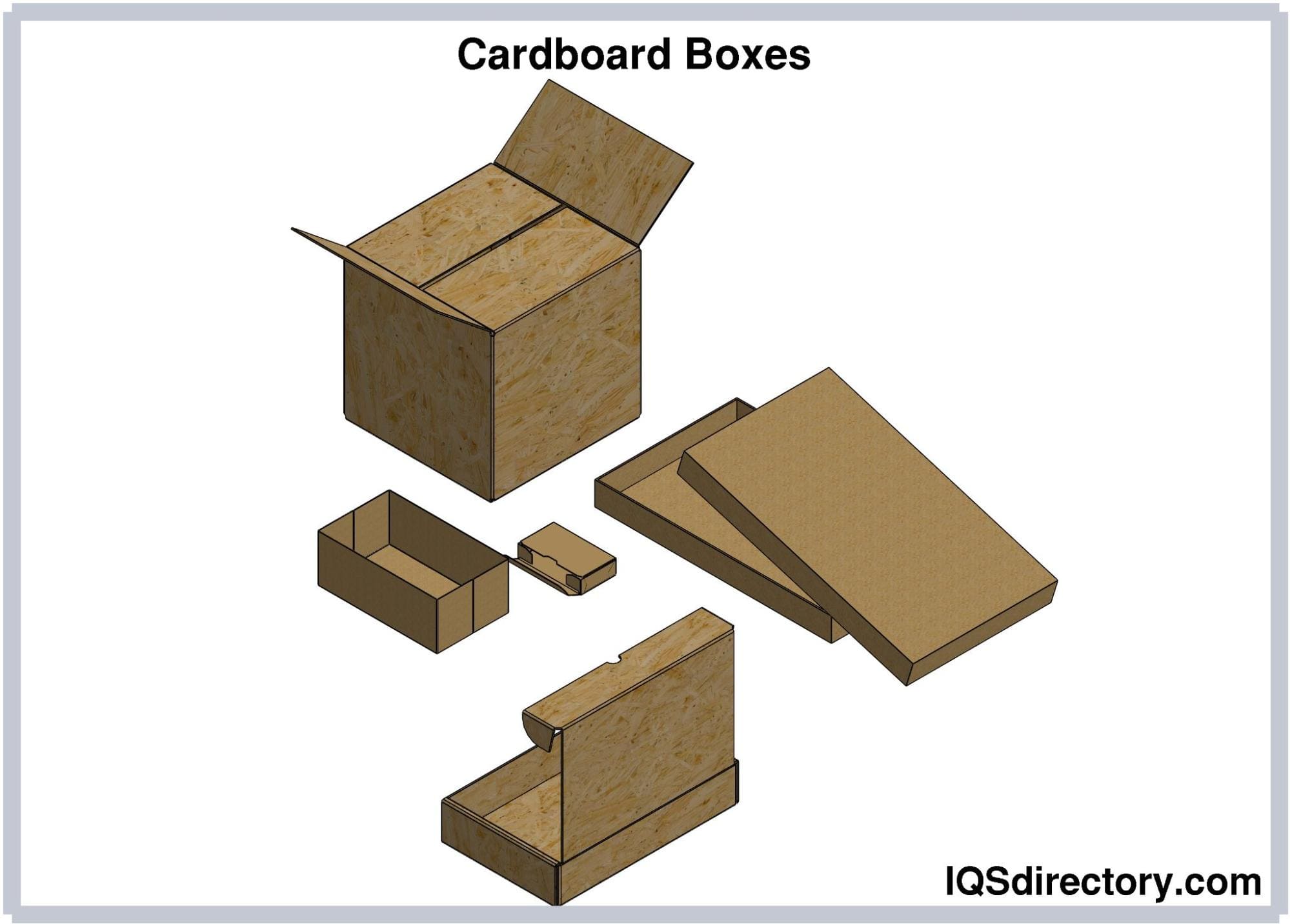

Paperboard is typically used to make folding boxes, referred to as product boxes. The dieline, printed with the box’s pattern and shape, is then cut into the desired shape. As the name implies, when the dieline is cut, these boxes must be folded into shape and adhered. Small things are ideal for putting in a folding box. It is portable and suitable for various goods, including CDs, books, and toys. Food, gloves, clothing, and other necessities can all be packed in a foldable box. The packaging market is very interested in folding boxes. Read More…

At Deluxe Packaging, our goal is to always create a cost-effective solution for you and to service you better than anyone else. We offer a full array of high quality corrugated boxes in a variety of shapes, sizes, materials, and features. Deluxe Packaging has a proven track record in custom packaging design and timely delivery.

At IPS Packaging, we take pride in being a trusted partner in the packaging industry, specializing in high-quality corrugated boxes designed to protect, ship, and present products with reliability and precision. We understand the critical role that corrugated packaging plays in supply chains, and our team is dedicated to developing durable, cost-effective solutions that meet the specific needs of ...

At Miller Supply, Inc., we take pride in providing high-quality corrugated boxes and packaging solutions designed to protect, organize, and enhance the presentation of our customers’ products. We understand that packaging plays a crucial role in both logistics and brand image, which is why we focus on producing corrugated boxes that combine strength, functionality, and visual appeal.

At DIA Packaging, we take pride in delivering expertly crafted corrugated boxes and packaging solutions designed to meet the unique demands of our customers. Our team is dedicated to producing durable, cost-effective, and environmentally conscious packaging that safeguards products during storage, handling, and transportation.

At Delmarva Corrugated Packaging, we take pride in delivering high-quality corrugated packaging solutions that meet the diverse needs of our customers. As a dedicated team, we have built our expertise around designing, manufacturing, and supplying corrugated boxes that are tailored to provide exceptional strength, durability, and reliability for a wide range of industries.

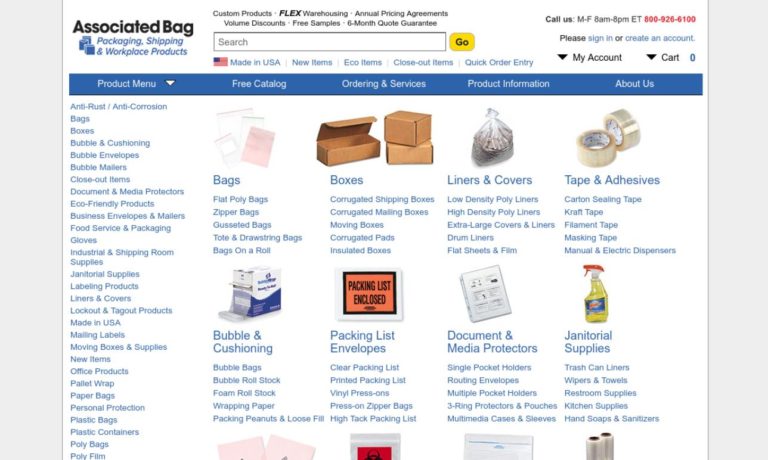

At Associated Bag, we have built a reputation among many industries by providing a broad range of high-quality corrugated boxes and exceptional customer service. Our 6-month quote guarantee is unequalled in our industry, giving our customers the flexibility to order whenever the time is best for them.Our line of boxes include corrugated shipping boxes, insulated boxes, and more. Contact...

More Folding Box Manufacturers

These boxes are in high demand mostly because they are strong and reliable enough to contain the contents inside. In addition, they are produced utilizing eco-friendly materials that protect the environment.

Folding boxes are made of commonly available materials like cardboard, paperboard, or corrugated cardboard and may be used for various packing needs. Their use is also relatively straightforward. Folding boxes come in various designs that can be used to package goods.

Types of Folding Boxes

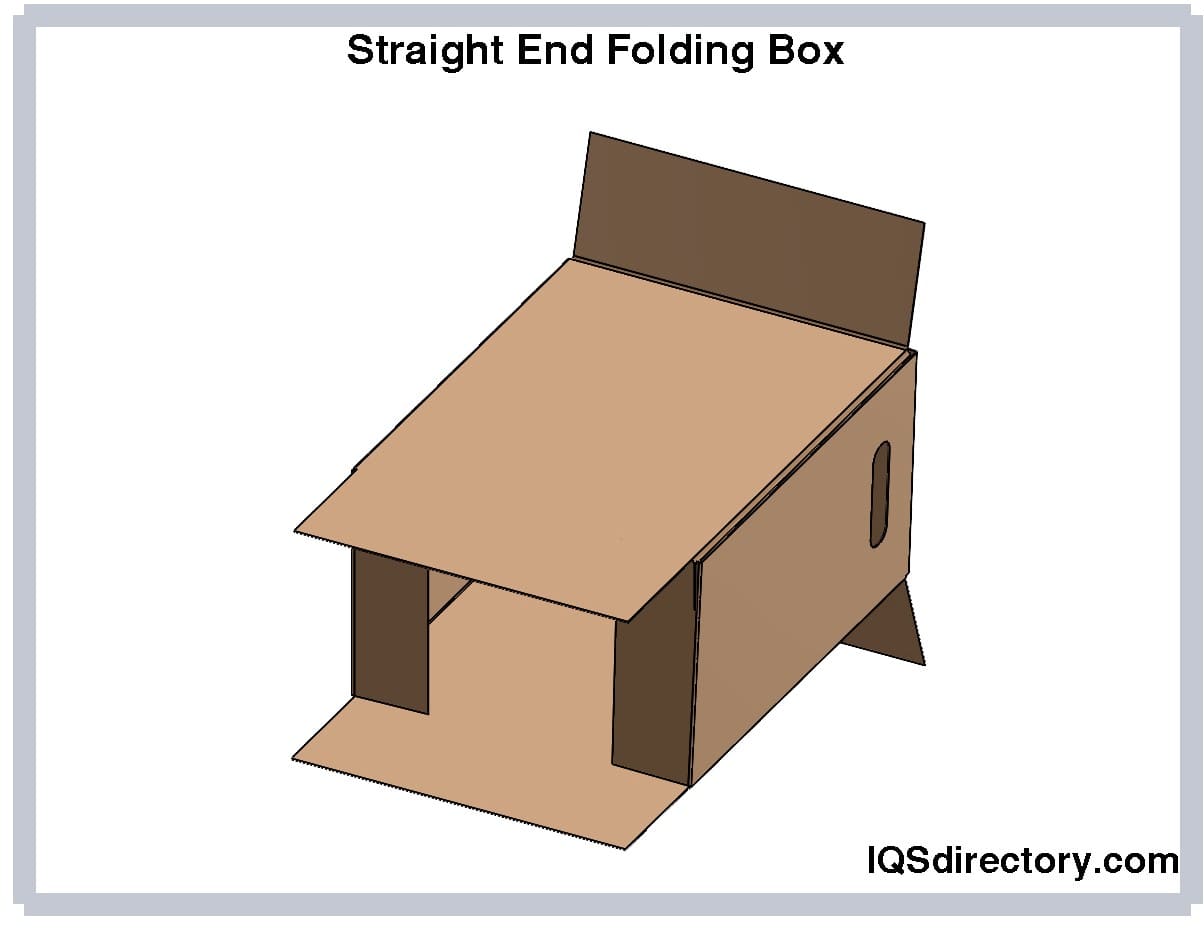

Straight Tuck End Boxes

The most popular box type utilized by retail businesses is a straight tuck end box, which can be used in any industry. The tuck end box has a front, a back, two sides, and two apertures. Both openings consist of two flaps that are fastened to the box's sides and fold inward, as well as a bigger flap that is fastened to the front of the box and folds over the side flaps before tucking into the rear of the box.

Uses for Straight Tuck End Boxes

- Putting packed goods on a shelf for retail sale or a point-of-purchase display

- When enclosing promotional items in branded packaging

- If distributing product samples to clients and promising new clients

- Whenever a dispenser cutout is utilized for packaging goods individually

Advantages of Straight Tuck End Boxes

- They are simple to put together.

- They are more aesthetically pleasing when put on retail or point-of-purchase displays.

- They can be exhibited on any flat surface and stacked neatly.

- Any lightweight product, gift, or promotional item would be ideal for them.

- They increase brand awareness when they are personalized with a company's branding.

- They increase the worth of the items contained inside.

- Both ends of the box can be opened to access them.

Reverse Tuck End Boxes

RTE boxes are the common name for this kind of box. These boxes are made so that the top closures face forward from the back and the bottom closures face backward from the front. This box is fairly simple to open and close while maintaining excellent quality. This folding box is quite strong and can be used for long-term packaging.

Uses of a Reverse Tuck End Box

- Reverse tuck end boxes feature less paper waste, which can result in cost savings.

- Whenever a unique box is required for the wrapping of customer presents

- If delivering product samples to consumers and promising new clients

Advantages of Reverse Tuck End Boxes

- They are simple to put together.

- Any packaging objective can be met by tailoring them.

- They lay flat and stack well.

- They are ideal for light objects.

- They are a fantastic choice for wholesale businesses or online retail establishments.

- The box is open on both ends.

- As opposed to straight tuck end boxes, they employ less material.

Seal End Boxes

Seal end boxes make product packaging simple. Seal end boxes are standard tuck-flap boxes with adhesive flaps that overlap on both sides and panels on the top or bottom that slide on top to allow safe but simple opening and shutting. Boxes with seal ends are great for product storage since they offer strength and simplicity to the manufacturing line. Seal end boxes are helpful for the safe and practical storage of goods, but customers also favor them because they are simple to open. Food items like ice cream and frozen foods are offered in seal end boxes with tear-open tabs that enable customers to open the box as needed quickly. Due to their easily torn sections, sealed end boxes with die-cut perforations are perfect for presenting electronics and other retail items that require quick access.

Advantages of Seal End Boxes

- They are ideal for transporting and moving around objects.

- They are effective in holding both light and delicate objects.

- These boxes are made from high-grade cardboard, which reduces the possibility of breakage.

- They are simple to put together, with two identical panels at the top and bottom.

Custom Tuck End Boxes

For packing delicate and pricey things, the custom tuck-end auto bottom boxes are exceptional since they enable brands to prevent product damage and loss during transit. They aid brands in developing respectable identities in the marketplace. Because they are lightweight, recyclable, and economical, brands may reduce packaging and transportation costs while still operating sustainably.

Choosing the Right Folding Boxes Supplier

To make sure you have the most productive outcome when purchasing Folding Boxes from a Folding Boxes Supplier, it is important to compare at least 5 Companies using our list of Folding Boxes manufacturers. Each Folding Boxes Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Folding Boxes business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Folding Boxes companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

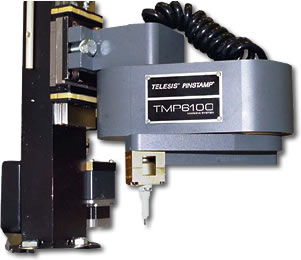

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services