One of the most widely used forms of packing is cardboard storage boxes. These boxes are made of sturdy paper and corrugated cardboard and are frequently used for storing, packing, or moving. They can be used for several things and are frequently recycled as storage boxes. They are widely used for various purposes, including moving, storing garbage in a cellar or closet, and carrying a box of valuable items. Read More…

At Deluxe Packaging, our goal is to always create a cost-effective solution for you and to service you better than anyone else. We offer a full array of high quality corrugated boxes in a variety of shapes, sizes, materials, and features. Deluxe Packaging has a proven track record in custom packaging design and timely delivery.

At IPS Packaging, we take pride in being a trusted partner in the packaging industry, specializing in high-quality corrugated boxes designed to protect, ship, and present products with reliability and precision. We understand the critical role that corrugated packaging plays in supply chains, and our team is dedicated to developing durable, cost-effective solutions that meet the specific needs of ...

At Miller Supply, Inc., we take pride in providing high-quality corrugated boxes and packaging solutions designed to protect, organize, and enhance the presentation of our customers’ products. We understand that packaging plays a crucial role in both logistics and brand image, which is why we focus on producing corrugated boxes that combine strength, functionality, and visual appeal.

At DIA Packaging, we take pride in delivering expertly crafted corrugated boxes and packaging solutions designed to meet the unique demands of our customers. Our team is dedicated to producing durable, cost-effective, and environmentally conscious packaging that safeguards products during storage, handling, and transportation.

At Delmarva Corrugated Packaging, we take pride in delivering high-quality corrugated packaging solutions that meet the diverse needs of our customers. As a dedicated team, we have built our expertise around designing, manufacturing, and supplying corrugated boxes that are tailored to provide exceptional strength, durability, and reliability for a wide range of industries.

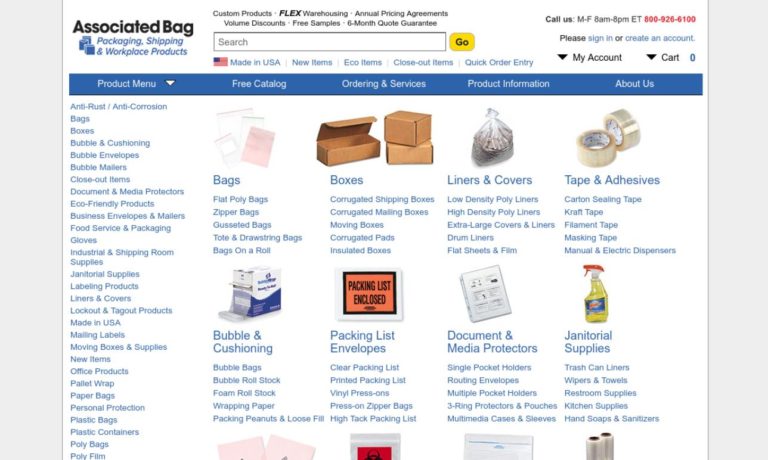

At Associated Bag, we have built a reputation among many industries by providing a broad range of high-quality corrugated boxes and exceptional customer service. Our 6-month quote guarantee is unequalled in our industry, giving our customers the flexibility to order whenever the time is best for them.Our line of boxes include corrugated shipping boxes, insulated boxes, and more. Contact...

More Cardboard Storage Box Manufacturers

How Cardboard Boxes Are Made: A Complete Guide for Buyers and Businesses

Introduction to Cardboard Boxes and Their Importance

Cardboard boxes are the cornerstone of modern packaging, shipping, and storage solutions. Used by retailers, manufacturers, e-commerce brands, and individuals alike, cardboard boxes provide a cost-effective, lightweight, and durable way to protect goods during transit, display products on shelves, and organize items in warehouses or homes. Understanding the manufacturing process, types, and advantages of cardboard boxes can help you make informed decisions when sourcing packaging materials for your business or personal needs.

Are you searching for the best cardboard box manufacturer or supplier? Do you need custom packaging, eco-friendly shipping boxes, or bulk cardboard cartons for your business? Explore the details below to discover how cardboard boxes are made, their diverse applications, benefits, and how to choose the right supplier for your requirements.

How Are Cardboard Storage Boxes Manufactured?

Cardboard storage boxes, often referred to as corrugated boxes, are constructed using a multi-layered process that combines strength, flexibility, and sustainability. Each box typically consists of two sturdy paper liners (the outer and inner facings) wrapped around a central corrugated medium—a fluted sheet that creates a robust, three-layered paper pulp structure. This unique design offers exceptional durability and cushioning, making cardboard boxes ideal for shipping, moving, and storage.

While brown is the most popular color for cardboard storage boxes due to its natural, unbleached look and recyclability, these boxes are also available in white, grey, or custom-printed finishes. The ability to print logos, graphics, and product information directly onto the box surface makes them a versatile branding tool for businesses across industries.

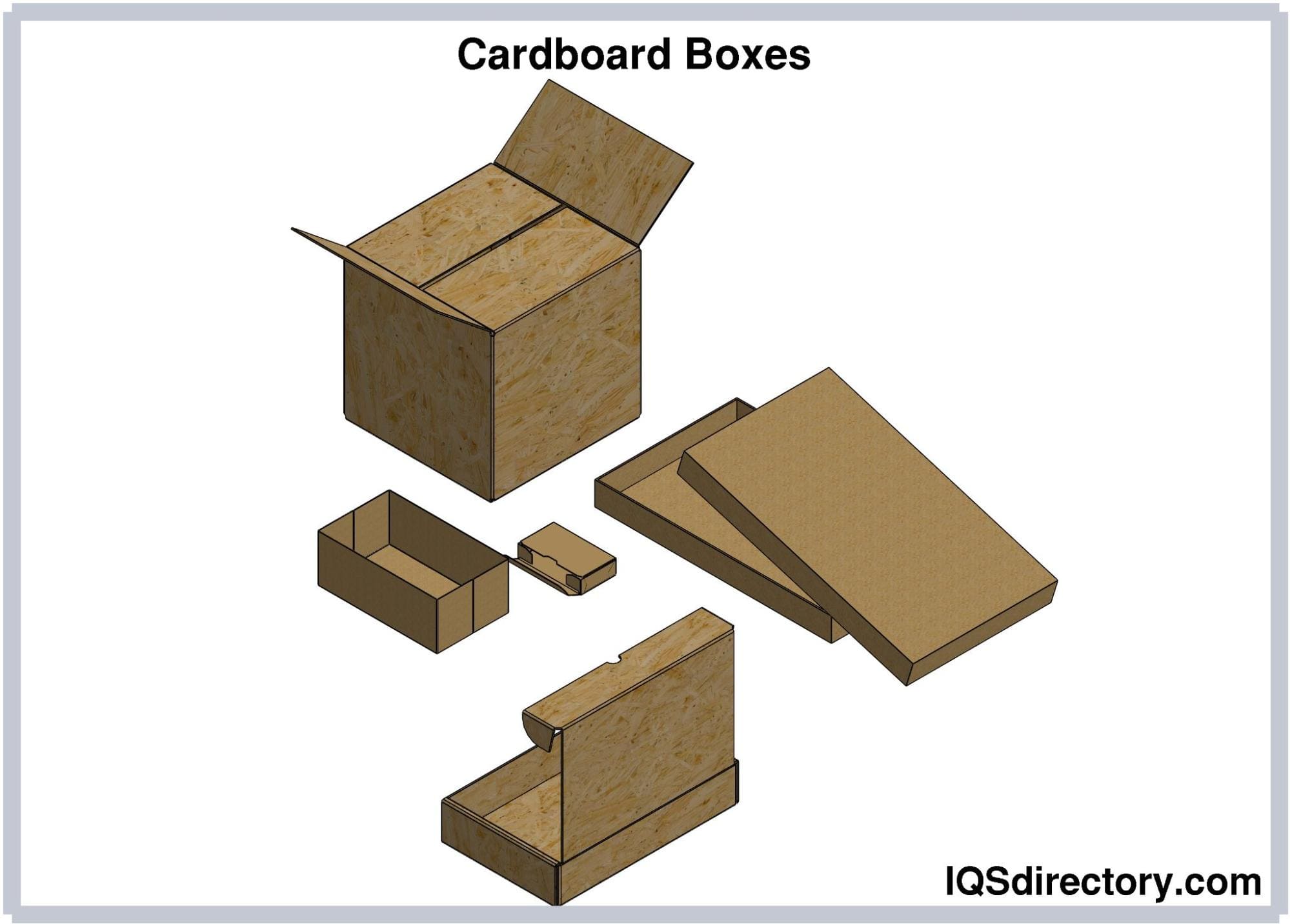

Shapes and Styles of Cardboard Boxes

Although commonly described as "boxes," cardboard containers are manufactured in various shapes and styles to suit different uses and industries. The standard rectangular cardboard box features six sides and is typically crafted from a single sheet of corrugated board, with four flaps on both the top and bottom for easy assembly and closure. Cylinder-shaped cardboard tubes are used for shipping posters, blueprints, or long items, while die-cut boxes can be custom-shaped for retail displays, gift packaging, and specialty products.

When assembling a cardboard box, the flaps are usually sealed with tape, glue, or industrial staples, but certain folding box styles allow for secure closure by interlocking the flaps—eliminating the need for adhesives. Learn more about folding boxes and custom die-cut packaging.

The Pulping Process: From Trees to Corrugated Cardboard

The journey from raw wood to finished cardboard starts with the pulping process—a critical step in paper and packaging manufacturing. High-quality paper pulp forms the basis for both the liners and the corrugated fluting in cardboard boxes. The process begins with carefully selected timber, typically from sustainably managed forests, which is cut, debarked, and chipped into manageable pieces.

Mechanical vs. Chemical Pulping

Two main technologies are used to convert wood chips into pulp suitable for cardboard production: mechanical pulping and chemical pulping.

- Mechanical Pulping: Involves pressing debarked logs against a rapidly rotating stone, creating a pulp by physically separating the wood fibers. Water is sprayed onto the stone to help release the fibers, but this method leaves much of the lignin (the natural adhesive in wood) intact, yielding a lower-quality, less durable paper product. Mechanical pulping is quick and cost-effective, making it suitable for some packaging applications where strength is not the primary concern.

- Chemical Pulping: Utilizes high temperatures and chemical solutions to dissolve lignin and separate cellulose fibers more thoroughly. The two main chemical pulping methods are the sulfate (kraft) process and the sulfite process. The kraft process, which uses alkaline solutions and sodium sulfate, is favored in cardboard manufacturing for producing exceptionally strong, high-quality paper pulp—ideal for heavy-duty shipping boxes and industrial cartons.

After pulping, the fibers are washed, screened, and processed into large rolls of linerboard (outer facings) and corrugated medium (inner fluting). These materials are then combined in a corrugator machine to form the finished corrugated board used in box manufacturing.

Types of Cardboard Boxes: Corrugated, Folding, and Specialty Packaging

When researching cardboard boxes for your business, it's important to know the key types available and their best-use scenarios:

- Corrugated Boxes: The most common type, featuring a fluted inner layer sandwiched between two flat linerboards. Corrugated boxes are renowned for their strength, shock resistance, and ability to protect goods during shipping. They are widely used for moving, shipping, and storage in e-commerce, logistics, manufacturing, and retail industries.

- Folding Cartons: Made from a single layer of paperboard (not corrugated), folding cartons are lighter and often used for packaging consumer goods such as cereal, cosmetics, pharmaceuticals, and retail items. They are easily customized with printing, die-cutting, and windowing options.

- Rigid Cardboard Boxes: Constructed from thick, compressed paperboard, rigid boxes offer premium protection and a high-end look—ideal for luxury products, electronics, and gift packaging. These boxes are often wrapped with decorative paper and feature custom inserts.

- Custom and Specialty Boxes: Die-cut boxes, display boxes, and specialty cartons can be tailored to unique product shapes, branding needs, and merchandising requirements. Many manufacturers offer custom box design services to help you create the perfect solution for your application.

What Are the Standard Sizes and Grades for Cardboard Boxes?

Cardboard boxes are available in a wide range of standard sizes, from small mailer boxes and shipping cartons to large wardrobe and pallet boxes. The strength and durability of a box are determined by its board grade (single wall, double wall, or triple wall) and the basis weight of the paper used. For heavy or fragile items, double-wall or triple-wall corrugated boxes are recommended. If you're unsure which box grade or size you need, ask your supplier for guidance based on your intended application.

Applications of Cardboard Boxes in Industry and Everyday Life

- Shipping and Logistics: Corrugated cardboard boxes are the backbone of the shipping and freight industry. They offer lightweight, stackable protection for products during transportation—whether by road, rail, air, or sea. The customizable nature of cardboard makes it easy to fit boxes to the exact dimensions of your products, reducing wasted space and shipping costs.

- Warehousing and Storage: Cardboard boxes are indispensable for organizing inventory in warehouses, retail stockrooms, and offices. By labeling boxes and stacking them efficiently on shelves or pallets, businesses can streamline inventory management and improve order fulfillment speed.

- Retail and Point of Sale: Branded cardboard packaging enhances the unboxing experience and communicates your brand identity. Retail-ready packaging, display boxes, and counter-top cartons can be custom-printed to attract customer attention and boost sales.

- Home Organization and Moving: For individuals, cardboard boxes are essential for moving house, decluttering, and seasonal storage. Their versatility and affordability make them the go-to choice for students, families, and small businesses alike.

- Creative and Eco-Friendly Uses: From DIY furniture and pet houses to school projects and upcycled crafts, the possibilities for reusing and repurposing cardboard are virtually endless. Cardboard is also biodegradable and widely recycled, making it a sustainable packaging solution.

Looking for innovative uses for cardboard boxes? Browse cardboard box manufacturer directories or get inspiration for your next packaging project.

Advantages and Key Benefits of Cardboard Boxes

- Strength-to-Weight Ratio: Despite being made from paper, corrugated cardboard boxes are engineered for maximum strength and durability. Their multi-layered construction absorbs shocks and protects products from damage, while remaining light enough to minimize shipping costs.

- Customizability: Cardboard boxes can be produced in virtually any size, shape, or print design. Whether you need small mailer boxes, large moving cartons, or custom-printed packaging for retail, manufacturers can tailor boxes to your exact specifications.

- Cost-Effectiveness: One of the primary drivers behind the widespread adoption of cardboard boxes is their low production cost. Affordable materials and manufacturing processes keep prices competitive, making cardboard boxes accessible for businesses of all sizes. The ability to buy in bulk further reduces per-unit costs.

- Eco-Friendliness and Recyclability: Cardboard is more than 80% recyclable and biodegradable, reducing environmental impact. Many boxes are made from recycled content, and most waste management companies offer cardboard recycling programs. By choosing recycled or recyclable boxes, businesses can enhance their sustainability credentials.

- Branding and Marketing Opportunities: With advanced printing techniques, cardboard boxes can be transformed into powerful branding tools. Vivid graphics, company logos, product information, and promotional messages can all be printed directly onto the box surface—elevating the customer experience and increasing brand recognition.

How to Choose the Right Cardboard Box Manufacturer or Supplier

Selecting the right cardboard storage boxes manufacturer or packaging supplier is critical for ensuring quality, reliability, and competitive pricing. When evaluating suppliers, consider the following decision factors:

- Product Range: Does the supplier offer the box sizes, styles, and customization options you need? Look for manufacturers with a comprehensive catalog, including corrugated boxes, folding cartons, rigid boxes, and specialty packaging.

- Minimum Order Quantities (MOQs): Some manufacturers require large minimum orders, while others cater to small businesses with flexible quantities. Be sure to confirm MOQs and lead times before placing an order.

- Quality Assurance: Reliable suppliers employ strict quality control processes and provide product samples for evaluation. Look for certifications such as ISO 9001 or FSC (Forest Stewardship Council) to ensure responsible sourcing and manufacturing.

- Customization Capabilities: If you require custom-printed boxes, seek out suppliers with advanced printing and die-cutting facilities. Many offer design support, prototype samples, and short-run digital printing for unique packaging needs.

- Sustainability Practices: Environmentally conscious buyers should ask about recycled content, biodegradable coatings, and participation in recycling programs. Choosing green packaging suppliers can help you meet corporate sustainability goals.

- Customer Service: Responsive communication, on-time delivery, and after-sales support are essential for a positive buying experience. Read testimonials and reviews to gauge supplier reliability.

- Pricing and Value: While cost is important, balance price with quality, service, and long-term supplier relationships. Request quotes from several suppliers to compare value and options.

To secure the most beneficial outcome when purchasing cardboard storage boxes, compare at least four suppliers using our Cardboard Storage Boxes directory. Each manufacturer profile highlights areas of expertise, capabilities, and a direct contact form for information or quotes. Use our proprietary website previewer to explore each company's specialties, then submit a simple RFQ (Request for Quote) to multiple businesses with a single message.

Questions to Ask When Researching Cardboard Box Suppliers

- What is the lead time for production and delivery?

- Can you provide samples or prototypes before placing a bulk order?

- What customization options are available for size, shape, and printing?

- Are your boxes made from recycled materials or certified sustainable sources?

- Do you offer design support or packaging consultation services?

- What are your payment terms and return policies?

Searching for the best supplier for your packaging needs? Compare top-rated box manufacturers, request free samples, or get a personalized quote today.

Frequently Asked Questions About Cardboard Boxes

What are the most common uses for cardboard boxes?

Cardboard boxes are primarily used for shipping, storage, moving, retail packaging, and product displays. Their versatility, cost-effectiveness, and recyclability make them the preferred choice in e-commerce, manufacturing, logistics, and residential applications.

How do I choose the right size and grade of cardboard box?

Consider the dimensions and weight of your items, the shipping method, and any special protection requirements. For heavier or fragile items, select double-wall or triple-wall boxes. Consult your supplier for industry-standard box sizes and recommendations based on your application.

Can cardboard boxes be customized for branding and special applications?

Yes, most manufacturers offer custom sizing, die-cutting, and printing capabilities. You can add your company logo, product information, or promotional graphics to enhance brand visibility and customer experience.

Are cardboard boxes environmentally friendly?

Absolutely. Cardboard is among the most recycled packaging materials worldwide. Many boxes are made from recycled content and can be recycled again after use, supporting a circular economy and reducing landfill waste.

What industries benefit most from using cardboard packaging?

Industries that rely heavily on cardboard packaging include e-commerce, food and beverage, pharmaceuticals, electronics, automotive, apparel, and home goods. Cardboard boxes are also essential in fulfillment centers, warehouses, and retail stores.

Ready to Source Cardboard Boxes? Start Your Search Today

Whether you need standard shipping cartons, custom-printed packaging, or specialty die-cut boxes, the right cardboard box manufacturer can help you optimize your packaging strategy, reduce costs, and improve your brand image. Use our directories, guides, and RFQ tools to connect with leading suppliers, request samples, and compare options for your next packaging project.

Start your search now:

Find Cardboard Box Manufacturers |

Explore Folding Box Options |

Browse Storage Boxes

For more information on cardboard packaging, sustainability, or custom box design, contact our team or check out our resource center for detailed guides and industry news.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services