Chipboard boxes are inexpensive, environmentally friendly, and a popular packaging option for consumer goods. Chipboard is made from pieces of recycled paper, wood pulp, sawdust, or chips that have been compressed by using heat and pressure and bonded by an adhesive material or resin. You often see chipboard or paperboard in brown or white, but most companies add colors or logos so they can be sold in stores. Read More…

At Deluxe Packaging, our goal is to always create a cost-effective solution for you and to service you better than anyone else. We offer a full array of high quality corrugated boxes in a variety of shapes, sizes, materials, and features. Deluxe Packaging has a proven track record in custom packaging design and timely delivery.

At IPS Packaging, we take pride in being a trusted partner in the packaging industry, specializing in high-quality corrugated boxes designed to protect, ship, and present products with reliability and precision. We understand the critical role that corrugated packaging plays in supply chains, and our team is dedicated to developing durable, cost-effective solutions that meet the specific needs of ...

At Miller Supply, Inc., we take pride in providing high-quality corrugated boxes and packaging solutions designed to protect, organize, and enhance the presentation of our customers’ products. We understand that packaging plays a crucial role in both logistics and brand image, which is why we focus on producing corrugated boxes that combine strength, functionality, and visual appeal.

At DIA Packaging, we take pride in delivering expertly crafted corrugated boxes and packaging solutions designed to meet the unique demands of our customers. Our team is dedicated to producing durable, cost-effective, and environmentally conscious packaging that safeguards products during storage, handling, and transportation.

At Delmarva Corrugated Packaging, we take pride in delivering high-quality corrugated packaging solutions that meet the diverse needs of our customers. As a dedicated team, we have built our expertise around designing, manufacturing, and supplying corrugated boxes that are tailored to provide exceptional strength, durability, and reliability for a wide range of industries.

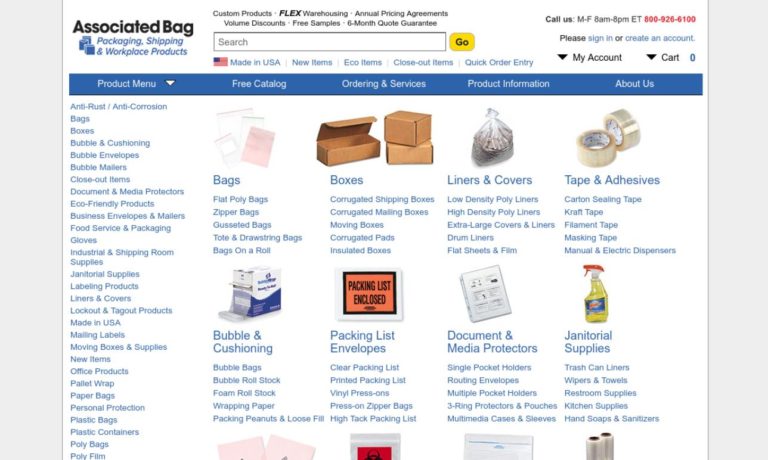

At Associated Bag, we have built a reputation among many industries by providing a broad range of high-quality corrugated boxes and exceptional customer service. Our 6-month quote guarantee is unequalled in our industry, giving our customers the flexibility to order whenever the time is best for them.Our line of boxes include corrugated shipping boxes, insulated boxes, and more. Contact...

More Chipboard Box Manufacturers

Comprehensive Guide to Chipboard Boxes: Applications, Manufacturing, and Industry Uses

Chipboard boxes, also known as paperboard boxes or carton boxes, are essential packaging solutions utilized across a diverse range of industries. Their versatility, cost-effectiveness, and eco-friendly nature make chipboard packaging a preferred choice for businesses that require reliable protection and appealing presentation of their products. If you’re wondering, “What are chipboard boxes used for?” or “How do chipboard boxes compare to corrugated boxes?”, this guide addresses those questions and more—helping you make informed packaging decisions for your business.

What Are Chipboard Boxes?

Chipboard boxes are a type of paper-based packaging made from recycled paper pulp and wood byproducts. Unlike corrugated cardboard boxes, which feature a fluted layer for added strength, chipboard packaging is made from a single, solid layer of compressed fibers. This construction gives chipboard boxes a smooth surface, making them ideal for custom printing and decorative finishes. Their lightweight nature, combined with customizable thickness, makes them an excellent choice for packaging a wide array of products.

Key Industries and Common Applications for Chipboard Boxes

Chipboard boxes are used in a variety of industries, each leveraging the unique properties of chipboard materials to meet specific packaging requirements. Below are some of the leading industries and use cases for chipboard packaging:

- Shipping and Logistics: When used for shipping, chipboard boxes are often coated with a waterproof finish to protect contents from moisture, rain, and other environmental hazards. Thinner layers of chipboard are used for lightweight protection, while thicker boards provide added rigidity and impact resistance as the outer box component.

- Food Processing and Food Packaging: The food industry relies on chipboard boxes for packaging cereals, snacks, frozen foods, and more. Food-grade coatings and laminations ensure these boxes meet hygiene regulations and preserve product freshness.

- Consumer Products and Retail: Many consumer goods, from cosmetics and electronics to health supplements and toys, are packaged in custom chipboard boxes. These boxes offer excellent printability for branding, product information, and eye-catching shelf appeal.

- Tool and Hardware Packaging: The tool industry frequently uses chipboard packaging for items such as drill bits, fasteners, and small hand tools. Sturdy chipboard boxes keep products organized and secure during transit and storage.

- Pharmaceuticals and Healthcare: Chipboard cartons are used for packaging medicines, medical devices, and health products. Tamper-evident closures and specialty coatings can be applied for safety and compliance.

- Stationery and Office Supplies: Many office products, including folders, envelopes, notepads, and paper reams, are packaged in chipboard boxes for efficient handling and presentation.

Most chipboard boxes are custom made to fit the specific dimensions and protection needs of the products they contain. Whether you need a box for retail shelves or bulk packaging for shipping, chipboard is adaptable to nearly any requirement.

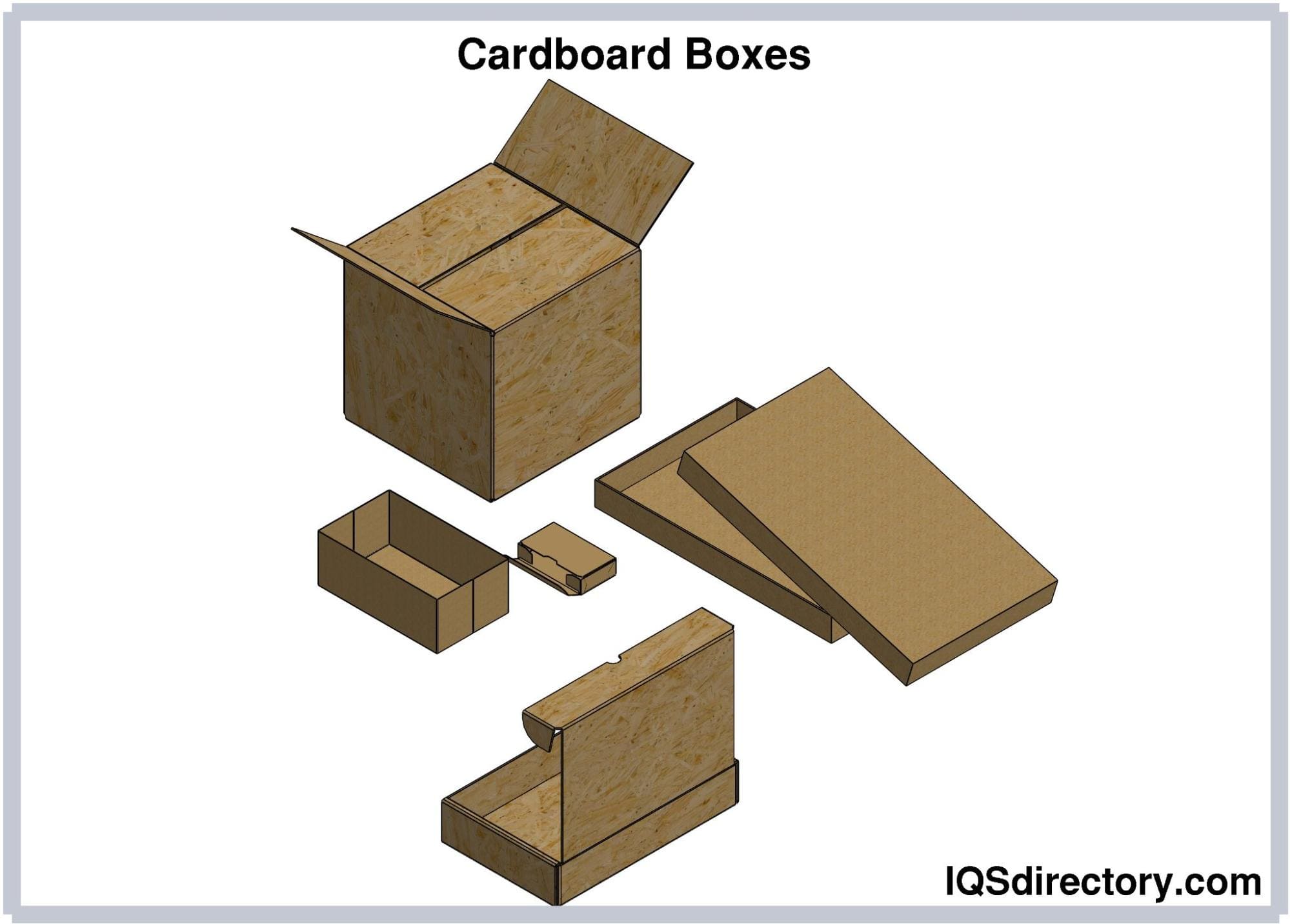

Types and Styles of Chipboard Boxes

Chipboard boxes are available in a variety of formats, each tailored to specific packaging needs:

- One-Piece Folding Cartons: Made from a single sheet of chipboard with flaps for closing, these cartons are common for food products, health and beauty items, and lightweight retail goods.

- Two-Piece Rigid Boxes: Consisting of a base and a separate lid, these boxes offer enhanced protection, a premium unboxing experience, and are often used for luxury packaging, gift boxes, and subscription boxes.

- Slipcases and Sleeves: These provide additional branding opportunities and protection when combined with an inner box or tray.

- Custom Die-Cut Boxes: Precisely cut to accommodate unique product shapes or presentation requirements, often used in promotional and specialty packaging.

Are you exploring custom chipboard packaging options? Contact chipboard box manufacturers to discuss design, printing, and finishing choices tailored to your product line.

Chipboard Box Manufacturing Process

The production of chipboard boxes involves several key steps, starting from raw material selection to the final box assembly. Understanding this process can help you evaluate the sustainability, quality, and suitability of chipboard packaging for your needs.

Raw Material Sourcing

Chipboard is made from recycled paper shreds, sawdust, and woodchips—making it an environmentally responsible packaging material. These raw materials are collected from post-consumer waste streams, lumber mills, and manufacturing byproducts, supporting a circular economy and reducing landfill waste.

Chipping and Pulping

Collected materials are fed into industrial chippers, where they are broken down into fine granules. The granulated pulp is then dried in large rotary dryers until it reaches a low moisture content, which is essential for strong adhesion and structural integrity in the finished board.

Adhesive Application and Pressing

Next, eco-friendly adhesives—often derived from natural or synthetic resins—are mixed into the dry pulp. The mixture is then pressed under high temperatures and immense pressure until the desired thickness and density are achieved. The combination of heat and adhesive causes the fibers to bond tightly, forming durable chipboard sheets.

Finishing and Surface Treatments

After cooling, chipboard sheets undergo treatments such as sanding, trimming, and surface coating. A waterproof finish may be applied to enhance durability, especially for shipping and food packaging applications. Decorative laminations or printed paper layers are added for retail and branded packaging.

Cutting, Scoring, and Assembly

The large chipboard sheets are cut down to custom sizes using precision die-cutting machines. Scoring lines are added for easy folding and assembly. Once shipped to box manufacturers or end-users, the chipboard material is folded along pre-scored lines and assembled into a box form—ready for packing and distribution.

Benefits of Chipboard Boxes

Choosing chipboard boxes for your packaging needs delivers a host of advantages that can positively impact your business and brand. If you’re comparing packaging solutions, consider the following benefits:

- Lightweight Yet Strong: Chipboard’s high strength-to-weight ratio makes it ideal for packaging products that require protection without adding excess shipping weight.

- Customizable and Printable: The smooth surface of chipboard accepts various printing techniques, including offset printing and digital printing, enabling vibrant graphics, logos, and product information for retail marketing.

- Eco-Friendly and Recyclable: Manufactured from recycled materials and fully recyclable after use, chipboard boxes support sustainability goals and appeal to environmentally conscious consumers.

- Cost-Effective Production: Chipboard packaging is generally more affordable than plastic or metal alternatives, offering excellent value for high-volume applications.

- Versatile Applications: Suitable for food packaging, pharmaceuticals, electronics, apparel, gifts, and more—chipboard boxes adapt to countless product types and industry needs.

- Efficient Storage and Shipping: Chipboard boxes ship and store flat, saving valuable warehouse space and reducing freight costs.

Wondering which packaging material is best for your products?

Compare chipboard boxes vs. corrugated boxes to find the right balance of cost, strength, and sustainability. Consider your product weight, fragility, and shipping requirements to make an informed choice.

Factors to Consider When Choosing Chipboard Packaging

When selecting chipboard boxes for your business, it’s important to evaluate several key decision factors to ensure optimal performance and cost-effectiveness:

- Product Size and Weight: Heavier or more delicate products may require thicker chipboard or reinforced designs.

- Moisture and Environmental Exposure: If your products will encounter humidity, rain, or other harsh conditions, request waterproof coatings or laminated finishes.

- Branding and Shelf Appeal: For retail packaging, prioritize high-quality printing and decorative finishes to maximize consumer impact.

- Custom Inserts and Compartments: Protect and organize multiple product components with custom die-cut inserts or partitions.

- Order Volume and Lead Time: Large production runs benefit from economies of scale, while short lead times may require partnering with local chipboard box manufacturers.

- Sustainability Requirements: Specify recycled content, recyclable coatings, and biodegradable adhesives to meet green packaging standards.

Not sure what thickness or coating you need? Ask a packaging specialist about the best chipboard grade for your application, or request samples to compare options firsthand.

Customization and Value-Added Features

Chipboard boxes can be fully customized to reflect your brand identity and enhance the customer experience. Explore the following customization options to make your packaging stand out:

- Custom Printing and Graphics: Showcase your logo, product imagery, instructions, and regulatory information with full-color printing.

- Specialty Coatings: Choose from matte, gloss, UV, or soft-touch finishes for added visual and tactile appeal.

- Embossing and Debossing: Add texture and dimension to your packaging with raised or recessed elements.

- Window Cutouts: Allow consumers to view the product inside while keeping it protected.

- Foil Stamping and Spot UV: Highlight premium features or branding elements for a luxurious look.

- Custom Inserts: Secure delicate or multiple items with die-cut foam, paperboard, or molded pulp inserts.

Looking to increase your product’s shelf presence? Work with a chipboard packaging designer to create unique structures and finishes that captivate your target audience.

Chipboard Boxes and Sustainability

As businesses and consumers place increased emphasis on sustainability and responsible sourcing, chipboard boxes stand out as a leading eco-friendly packaging solution. Here’s how chipboard supports green initiatives:

- High Recycled Content: Most chipboard packaging is made from post-consumer recycled paper and wood fibers, diverting waste from landfills.

- Recyclable and Biodegradable: After use, chipboard boxes can be recycled through standard curbside programs or composted in industrial facilities.

- Reduced Carbon Footprint: Lightweight chipboard requires less energy to transport and produce compared to heavier alternatives like plastic or metal.

- Sustainable Sourcing: Many chipboard manufacturers adhere to FSC (Forest Stewardship Council) and SFI (Sustainable Forestry Initiative) certification standards.

How can switching to chipboard boxes help your business meet sustainability goals? Evaluate your current packaging materials and ask about eco-friendly certifications, recycled content, and closed-loop recycling programs.

Frequently Asked Questions About Chipboard Boxes

- What is the difference between chipboard and corrugated cardboard?

- Chipboard is a single-layer, solid paperboard material known for its smooth surface and printability, while corrugated cardboard features a wavy (fluted) inner layer sandwiched between two liners for added strength and cushioning. Chipboard is ideal for lightweight and retail packaging; corrugated cardboard is better for shipping heavier items.

- Can chipboard boxes be used for food packaging?

- Yes, chipboard boxes are widely used in the food industry for dry goods, frozen foods, and snacks. Food-grade coatings and laminations are applied to meet safety standards and protect against moisture and grease.

- How customizable are chipboard boxes?

- Chipboard boxes offer extensive customization, including size, shape, color, printing, finishes, and internal inserts. This flexibility allows businesses to create packaging that aligns with their branding and functional requirements.

- Are chipboard boxes environmentally friendly?

- Absolutely. Chipboard is typically made from recycled materials and is both recyclable and biodegradable, making it a sustainable choice for eco-conscious brands.

- What are the minimum order quantities for custom chipboard boxes?

- Minimum order quantities vary by manufacturer and project complexity. Many suppliers accommodate both small runs for specialty products and large-scale orders for nationwide distribution. Ask your supplier about their minimums and lead times.

How to Source Chipboard Boxes for Your Business

If you’re ready to upgrade your packaging or need a reliable supplier of chipboard boxes, follow these steps to ensure a successful purchase:

- Define your product requirements: size, weight, protection level, branding, and sustainability needs.

- Research reputable chipboard box manufacturers and packaging suppliers with experience in your industry.

- Request samples and quotes to compare quality, pricing, and turnaround times.

- Evaluate customization options and value-added services, such as design support and inventory management.

- Confirm certifications for food safety, sustainability, or regulatory compliance if needed.

- Place your order and coordinate delivery timelines to align with your production schedule.

Ready to get started? Find a chipboard box manufacturer or request a quote today to discover how chipboard packaging can elevate your brand and streamline your operations.

Conclusion: Why Choose Chipboard Boxes?

Chipboard boxes are a highly versatile, affordable, and sustainable packaging solution suitable for a broad spectrum of industries—including food, retail, pharmaceuticals, tools, and consumer goods. Their customizable nature means you can create packaging that not only protects your products but also enhances your brand image and supports your environmental goals. Whether you need basic folding cartons or premium rigid boxes, chipboard packaging delivers performance, value, and flexibility.

Still have questions about chipboard boxes or want to explore custom packaging solutions? Contact a packaging expert or browse our comprehensive chipboard and cardboard box options for more information and inspiration.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services