Corrugated boxes are a type of container used in shipping and storage that are ubiquitous across thousands of industries. Although people often refer to them erroneously as cardboard boxes, they are made of corrugated materials. Most typically the corrugated–meaning fluted, rippled or ridged—material from which they are made is corrugated fiberboard. This consists of two flat sheets sandwiched above and below a corrugated sheet in layers. Read More…

At Deluxe Packaging, our goal is to always create a cost-effective solution for you and to service you better than anyone else. We offer a full array of high quality corrugated boxes in a variety of shapes, sizes, materials, and features. Deluxe Packaging has a proven track record in custom packaging design and timely delivery.

At IPS Packaging, we take pride in being a trusted partner in the packaging industry, specializing in high-quality corrugated boxes designed to protect, ship, and present products with reliability and precision. We understand the critical role that corrugated packaging plays in supply chains, and our team is dedicated to developing durable, cost-effective solutions that meet the specific needs of ...

At Miller Supply, Inc., we take pride in providing high-quality corrugated boxes and packaging solutions designed to protect, organize, and enhance the presentation of our customers’ products. We understand that packaging plays a crucial role in both logistics and brand image, which is why we focus on producing corrugated boxes that combine strength, functionality, and visual appeal.

At DIA Packaging, we take pride in delivering expertly crafted corrugated boxes and packaging solutions designed to meet the unique demands of our customers. Our team is dedicated to producing durable, cost-effective, and environmentally conscious packaging that safeguards products during storage, handling, and transportation.

At Delmarva Corrugated Packaging, we take pride in delivering high-quality corrugated packaging solutions that meet the diverse needs of our customers. As a dedicated team, we have built our expertise around designing, manufacturing, and supplying corrugated boxes that are tailored to provide exceptional strength, durability, and reliability for a wide range of industries.

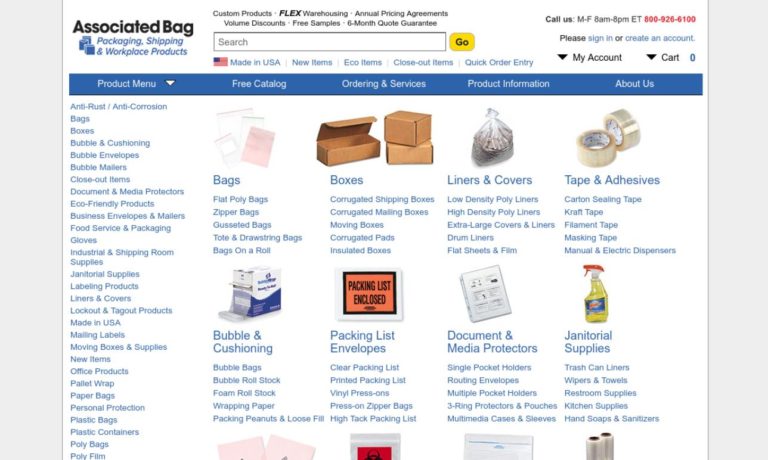

At Associated Bag, we have built a reputation among many industries by providing a broad range of high-quality corrugated boxes and exceptional customer service. Our 6-month quote guarantee is unequalled in our industry, giving our customers the flexibility to order whenever the time is best for them.Our line of boxes include corrugated shipping boxes, insulated boxes, and more. Contact...

More Corrugated Box Manufacturers

Corrugated Box Applications

Versatile Packaging Solutions for Every Industry

Corrugated boxes, manufactured from corrugated fiberboard, have become the backbone of modern packaging and shipping due to their unmatched strength, durability, and adaptability. These boxes are engineered with a fluted (wavy) layer nestled between two smooth linerboards, delivering exceptional structural integrity and impact absorption. Within industrial and commercial environments, corrugated packaging is relied upon for a multitude of applications—ranging from the safe transportation of fragile electronics to the efficient storage of inventory in warehouses. Their lightweight construction, cost-effectiveness, and eco-friendly recyclability make corrugated boxes the preferred packaging solution across sectors such as manufacturing, logistics, retail, food and beverage, pharmaceuticals, automotive, and e-commerce. This comprehensive guide explores the key industrial uses, benefits, and decision factors for corrugated boxes, helping businesses understand how these versatile containers can enhance operational efficiency and product protection.

What Are Corrugated Boxes in Industrial Contexts?

Corrugated boxes are formed from corrugated cardboard—a robust packaging material constructed by gluing a fluted (corrugated) medium between two flat sheets of paperboard, also called linerboard. The unique fluted structure creates air pockets that provide both cushioning and strength, enabling the boxes to withstand stacking, compression, and rough handling. In industrial applications, corrugated boxes are often custom-designed for specific requirements; options include single-wall, double-wall, or triple-wall constructions depending on required strength, along with special features like moisture resistance, anti-static liners, custom dividers, and printed branding. Corrugated cardboard packaging is a mainstay for shipping, storage, product protection, in-store displays, and more—delivering a balance of high performance, sustainability, and affordability for modern supply chains.

Key Industrial Applications of Corrugated Boxes

Corrugated boxes are integral to logistics, warehousing, manufacturing, distribution, and retail operations. Below, we detail the primary use cases and applications for corrugated packaging in various industries:

-

- Shipping and Transportation

Corrugated boxes are the industry standard for shipping and transporting goods, thanks to their superior protective qualities and stacking strength.

-

- Product Shipping: Sectors like automotive, electronics, and consumer goods depend on corrugated shipping boxes to deliver products—such as car parts, consumer electronics, appliances, and retail merchandise—safely over long distances.

- Bulk Material Transport: In agriculture and food processing, large corrugated cartons are used for the mass shipment of grains, fresh produce, frozen foods, and more. Many are engineered with moisture-resistant coatings for perishables.

- Palletized Loads: Corrugated boxes are designed for optimal stacking on pallets, supporting efficient freight handling in warehousing and distribution centers.

- Benefits: Corrugated boxes provide outstanding protection from shocks, vibrations, and compression forces, ensuring products arrive intact. Their relatively low weight reduces freight costs and carbon footprint.

-

- Storage and Warehousing

Corrugated boxes are essential for inventory management and storage in warehouses, distribution centers, and backrooms.

-

- Inventory Management: In manufacturing and retail, corrugated cartons provide a cost-effective method for storing raw materials, components, finished products, and seasonal goods. Clearly labeled boxes streamline identification and tracking.

- Archival Storage: Sectors like pharmaceuticals, legal, and banking use archival-grade corrugated boxes—often acid-free—for long-term storage of documents, samples, or sensitive records.

- Temporary Storage: Corrugated boxes hold semi-finished assemblies, packaging materials, and goods awaiting shipment, supporting just-in-time production and lean inventory practices.

- Benefits: Their modular, stackable design maximizes use of warehouse space, while corrugated board’s density shields contents from dust, light, pests, and moisture.

-

- Product Protection in Manufacturing

Corrugated boxes safeguard products and components during manufacturing and assembly, preventing costly damage and loss.

-

- Component Packaging: Automotive and electronics manufacturers rely on corrugated boxes with custom inserts or dividers to shield delicate parts (circuit boards, sensors, engine components) during handling and transport.

- Heavy Machinery Parts: Double-wall and triple-wall corrugated boxes offer the strength needed for bulky, heavy, or irregularly shaped industrial parts.

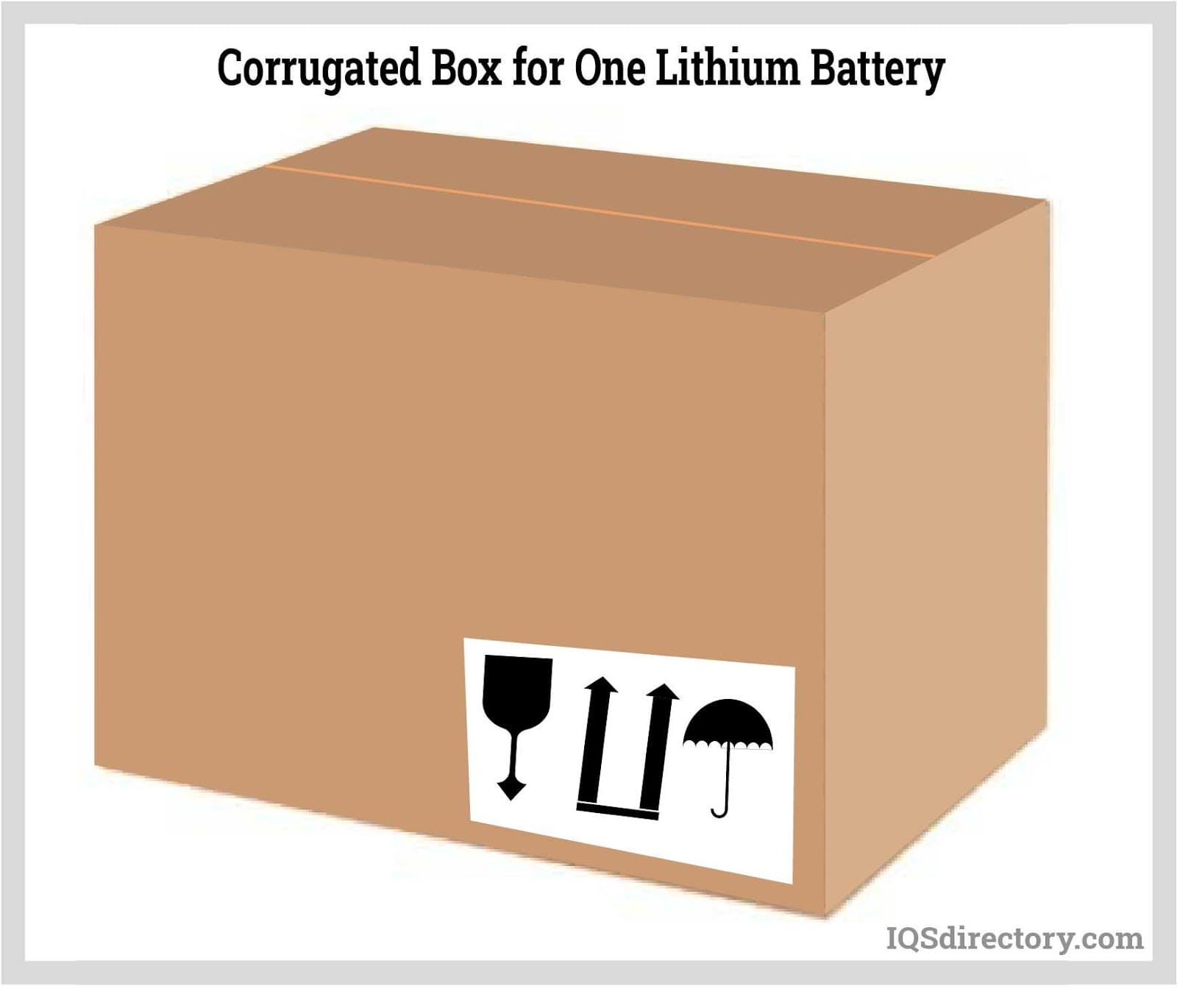

- Hazardous Materials: UN-rated corrugated boxes, designed to comply with hazardous material shipping regulations, are widely used in chemical, pharmaceutical, and laboratory applications.

- Benefits: The air-cushioned flutes of corrugated packaging absorb shocks, minimize vibration, and mitigate static discharge, helping maintain product quality and reduce waste.

-

- Food and Beverage Industry

The food and beverage sector trusts corrugated packaging for safe, hygienic, and efficient transport and display of both perishable and shelf-stable products.

-

- Fresh Produce Packaging: Corrugated boxes—often with ventilation holes and water-resistant coatings—are essential for shipping fruits, vegetables, seafood, and frozen foods while maintaining freshness and food safety.

- Beverage Distribution: Multi-pack corrugated cartons transport bottled and canned beverages, offering stack strength and protection against breakage.

- Retail Display: Shelf-ready and point-of-purchase (POP) corrugated displays enable retailers to move product directly from shipping to sales floor, improving merchandising efficiency.

- Benefits: Corrugated boxes meet FDA and food industry standards, are fully recyclable, and can be tailored for moisture control and branding needs.

-

- E-Commerce and Retail Distribution

With the explosive growth of online retail, corrugated shipping boxes are more important than ever for direct-to-consumer fulfillment and last-mile delivery.

-

- Order Fulfillment: E-commerce businesses depend on custom corrugated boxes for shipping everything from electronics and books to fashion and cosmetics. Right-sized packaging reduces shipping costs and minimizes waste.

- Subscription Boxes: Monthly subscription services select corrugated packaging for its protective qualities, printability, and unboxing appeal—enhancing the customer experience.

- Retail Distribution: Brick-and-mortar and omnichannel retailers use corrugated containers to distribute merchandise efficiently and securely from central warehouses to individual stores.

- Benefits: Corrugated boxes are highly customizable for branding, recyclable to meet consumer sustainability preferences, and provide robust protection during unpredictable shipping conditions.

-

- Pharmaceutical and Medical Industry

The pharmaceutical and healthcare sectors require corrugated packaging that meets stringent regulatory and hygiene standards.

-

- Medicine Packaging: Corrugated boxes with insulated liners or temperature-control features are used for shipping pharmaceuticals, vaccines, and sensitive biotech products.

- Medical Equipment: Large or custom-shaped corrugated containers protect diagnostic devices, hospital beds, and other medical equipment during transit.

- Sterile Storage: Hospitals and clinics use sterile corrugated boxes for storage and distribution of medical supplies such as syringes, bandages, and PPE.

- Benefits: Boxes can be engineered for tamper-evidence, regulatory compliance, and protection against temperature fluctuations, ensuring patient safety and product integrity.

-

- Automotive Industry

Corrugated packaging supports the automotive supply chain at every stage, from component manufacturing to aftermarket parts distribution.

-

- Parts Packaging: Corrugated boxes with molded inserts, dividers, or foam protect sensitive automotive parts like spark plugs, bearings, and filters during transport and storage.

- Aftermarket Distribution: Automotive parts retailers and service centers receive replacement parts in heavy-duty corrugated shipping cartons designed for durability and ease of handling.

- Heavy-Duty Applications: Triple-wall corrugated packaging is essential for shipping engines, transmissions, and other large, heavy components.

- Benefits: Corrugated boxes are cost-effective, minimize damage rates, and streamline logistics for OEM and aftermarket automotive applications.

-

- Chemical and Hazardous Materials Handling

The chemical industry depends on specialized corrugated packaging to ensure safety and compliance during the transport of dangerous goods.

-

- UN-Rated Boxes: Corrugated containers certified by the United Nations (UN) are required for shipping hazardous materials, including chemicals, solvents, and regulated waste.

- Bulk Packaging: Corrugated boxes with special liners or inner containment systems provide secure packaging for powdered, granular, or liquid chemicals.

- Benefits: UN-certified corrugated boxes meet rigorous global shipping standards, protect workers and the environment, and deliver a cost-effective alternative to rigid containers.

-

- Electronics and Technology Sector

Electronics manufacturers count on corrugated packaging for safe, anti-static transport and storage of high-value devices and components.

-

- Device Packaging: Corrugated boxes equipped with anti-static foam or liners are used to ship and store computers, monitors, servers, and other electronics, reducing the risk of static discharge and physical damage.

- Component Storage: Electronic manufacturing facilities use small corrugated boxes to organize and protect sensitive components such as microchips and capacitors.

- Benefits: Corrugated packaging provides excellent shock absorption, can be tailored with custom inserts, and ensures the secure delivery of valuable technology products.

Benefits of Corrugated Boxes in Industrial Applications

Why are corrugated boxes the packaging material of choice for so many businesses? Here are the core advantages:

-

- Durability and Strength: The fluted design delivers outstanding resistance to compression and stacking—ideal for heavy-duty shipping and storage.

- Product Protection: Corrugated packaging absorbs shocks, minimizes vibration, and shields against environmental hazards, reducing product loss during transit.

- Cost-Effectiveness: Corrugated boxes are inexpensive to produce and transport compared to alternatives like wood crates or plastic bins.

- Sustainability: Made from renewable, recyclable paper fibers, corrugated boxes support corporate sustainability goals and reduce landfill waste.

- Customizability: Corrugated packaging is easily tailored for any application, with options for custom sizing, coatings, inserts, and high-quality printing for branding and compliance labeling.

- Printability: The smooth surfaces of corrugated boxes are perfect for custom graphics, barcodes, handling instructions, and marketing messages, helping brands stand out and meet regulatory requirements.

- Recyclability: Used corrugated boxes can be recycled multiple times, supporting circular economy initiatives and reducing overall packaging costs for businesses.

Factors to Consider When Using Corrugated Boxes in Industrial Applications

Looking to optimize your packaging strategy? Consider these key decision factors when selecting corrugated boxes for your business:

-

- Box Strength: Choose between single-wall, double-wall, or triple-wall corrugated construction based on the weight, fragility, and stacking requirements of your products.

- Environmental Conditions: Evaluate whether your application needs moisture-resistant, wax-coated, or anti-static packaging—critical for food, agricultural, or electronic items.

- Regulatory Compliance: Ensure your corrugated packaging complies with relevant standards, such as UN certification for hazardous materials or FDA approval for food-grade applications.

- Customization Needs: Specify additional features like die-cut handles, ventilation holes, foam inserts, or tamper-evident seals to enhance product protection and usability.

- Branding and Printability: Leverage the large surface area of corrugated boxes for custom printing, logos, and product information, improving brand visibility and end-user engagement.

- Supply Chain Integration: Select suppliers who can provide just-in-time delivery, inventory management, and design support to streamline your operations.

History of Corrugated Boxes

Corrugated paper materials have been at the heart of packaging innovation for over 150 years. Before the industrialization of paper manufacturing, packaging was a luxury—handmade, labor-intensive, and expensive. The Industrial Revolution’s advances in wood pulp processing in the mid-19th century made paper products, including corrugated packaging, affordable and accessible on a mass scale.

The first patent for corrugated paper was granted in the United Kingdom in the 1850s, initially as a hat liner. Corrugated board as a packaging material emerged in the 1870s when American inventor Albert Jones patented a single-faced board for shipping. Oliver Long advanced the technology in 1874 with corrugated fiberboard—two flat faces encasing a central corrugated layer. That year, G. Smyth’s invention of the corrugator machine revolutionized mass production.

Swedish chemist Carl Dahl’s development of kraft paper in 1884 was another milestone, creating a strong, tear-resistant liner from wood pulp. By 1890, printer Robert Gair’s accidental discovery of the box-making process spurred the widespread adoption of corrugated boxes for shipping. Initially used for fragile items like ceramics and glass, corrugated boxes soon replaced wooden crates for farm produce, consumer goods, and industrial products. By the 1990s, US manufacturers were producing over 25 million tons of corrugated fiberboard annually—testament to the material’s enduring strength, versatility, and economy.

How Corrugated Boxes Are Made

Kraft paper, recognized for its strength and resilience, is the primary material used in the manufacture of corrugated boxes. Some specialty boxes may use corrugated plastic for added strength or moisture resistance, but kraft paper remains the gold standard for most applications.

The manufacturing process begins in the paper mill, where pine wood is stripped, chipped, and processed through the kraft (sulfate) method. Here, wood fibers are separated using an alkaline solution, resulting in a fibrous pulp. This pulp is then dehydrated and pressed into heavy-duty paper using Fourdrinier machines. The final kraft paper is rolled and shipped to corrugating plants.

In the corrugating plant, large corrugator machines—sometimes over 300 feet long—soften and flute the kraft paper using heat, moisture, and pressure. The fluted medium is sandwiched between two sheets of linerboard and glued with a cornstarch-based adhesive. The resulting corrugated fiberboard is dried, trimmed, cut into blanks, and sometimes finished with waterproof or glossy coatings for added protection and visual appeal.

Modern corrugated boxes consist of three layers: an inner liner, a fluted middle layer for cushioning and support, and an outer liner that provides strength and printability. Box-making machines then slot, score, and fold the blanks into flat, shippable forms. Typically sold in bulk bundles, these boxes are assembled on demand for efficient storage and logistics.

Key Manufacturing Considerations:

- Flute Size and Board Strength: Corrugated fiberboard comes in various flute sizes (A, B, C, E, F, etc.), each offering different compression resistance and cushioning properties.

- Environmental Impact: Many manufacturers now use recycled content and sustainable forestry practices to reduce the carbon footprint of corrugated packaging.

- Customization: Die-cutting, digital printing, and specialty coatings allow for fully customized packaging solutions tailored to unique product requirements.

- Quality Control: Rigorous testing ensures boxes meet strength, durability, and regulatory standards for specific applications, such as food contact or hazardous material transport.

Types of Boxes and Corrugated Fiberboard

While the terms “corrugated,” “cardboard,” and “paperboard” are sometimes used interchangeably, professionals distinguish between them for accuracy. “Corrugated fiberboard” refers specifically to the three-layered kraft paperboard used in most shipping and storage boxes. “Paperboard” is a heavier paper used for lighter packaging, while “chipboard” is recycled paper pressed for use in items like cereal boxes and board games.

Corrugated fiberboard is defined by the presence of flutes—pleats or ripples that trap air, enhancing cushioning and shock absorption. The number, size, and spacing of these flutes influence a box’s thickness, strength, and print surface area. Smaller flutes (E, F) are ideal for retail packaging and custom printing; larger flutes (A, C) provide maximum cushioning for shipping heavy or fragile goods.

Common Box Types and Customization Options:

- Regular Slotted Container (RSC): The most common shipping box, featuring flaps of equal length for easy assembly and closure.

- Die-Cut Boxes: Custom-shaped boxes produced with precision dies or lasers for unique product dimensions and shapes.

- Telescoping Boxes: Two-piece boxes for long or irregularly shaped items, often used in the automotive and electronics industries.

- Folder Boxes: Designed to wrap around products and provide extra protection for books, artwork, or flat goods.

- Custom Boxes: Engineered for specific needs, with dividers, foam inserts, wax or moisture-resistant coatings, and branded printing.

- Specialty Finishes: Laminated, bleached, or mottled exteriors for premium appearance or specific branding requirements. White and natural brown boxes are most prevalent.

Need help choosing the right box style or fiberboard for your product? Ask our experts: What’s the best corrugated box for my industry?

Corrugated Box Benefits

Corrugated boxes and containers provide a host of advantages that make them the go-to packaging solution for businesses large and small:

- Sustainability: Corrugated packaging is recyclable and often made with renewable materials, supporting green supply chains and circular economy initiatives.

- Affordability: Lightweight yet durable, corrugated boxes are inexpensive to manufacture, transport, and store, driving down total packaging costs.

- Versatility: From shipping heavy machinery to displaying consumer goods on retail shelves, corrugated boxes adapt to nearly any application.

- Printability: Their smooth surfaces provide an excellent canvas for marketing, branding, instructions, or regulatory information.

- Durability: Engineered to withstand impacts, stacking, and rough handling, corrugated boxes keep goods safe from origin to destination.

- Ease of Use: Boxes ship and store flat, saving space, and can be quickly assembled as needed.

However, corrugated boxes do have some limitations. They are generally not suitable for shipping very heavy items without additional reinforcement or for environments where strict hygiene is required (e.g., certain medical supplies or hospital food storage), as the paper fibers can absorb liquids or harbor pests if not properly treated. For high-security or contamination-sensitive applications, consider consulting with a packaging engineer to evaluate specialty materials or coatings.

Choosing the Right Corrugated Box Manufacturer

Selecting a corrugated box manufacturer is a critical decision for businesses that rely on packaging for shipping, storage, and product protection. A trusted supplier ensures your packaging meets performance requirements, regulatory standards, and branding needs. IQSDirectory.com, an industry-leading online platform for sourcing industrial suppliers, streamlines the process of finding reputable corrugated box manufacturers across North America. Use this step-by-step guide to find and vet suppliers that align with your business objectives.

Step 1: Define Your Corrugated Box Requirements

Before searching, outline your specific packaging needs. Consider:

-

- Application: What are you packaging—electronics, food, pharmaceuticals, automotive parts? Each requires different features (e.g., moisture resistance, anti-static liners, UN-rated certification).

- Box Strength: Determine whether you need single-wall, double-wall, or triple-wall construction for your products’ weight and fragility.

- Environmental Factors: Will boxes be exposed to humidity, temperature extremes, or rough handling?

- Special Features: Require custom printing, foam inserts, dividers, or shelf-ready designs for retail?

- Compliance: Ensure boxes meet relevant standards (FDA, UN, industry-specific).

Having clear requirements expedites the search for a manufacturer that can deliver tailored solutions for your sector.

Step 2: Search the Corrugated Box Category on IQSDirectory.com

Navigate to IQSDirectory.com and enter search terms like “corrugated box manufacturers,” “custom corrugated boxes,” “corrugated packaging,” or “shipping boxes.” Use filters to refine by state or region (e.g., California, Illinois, Texas, Canada) for local delivery and service advantages.

Browse related categories such as “Corrugated Packaging,” “Cardboard Boxes,” and “Shipping Containers” to explore a broader range of suppliers and solutions.

Step 3: Evaluate Manufacturer Profiles and Capabilities

IQSDirectory.com provides detailed company profiles, including:

-

- Contact Information: Phone, email, website, and geographic location.

- Product Descriptions: Overview of standard and custom corrugated boxes, shipping cartons, food-grade boxes, and specialty packaging solutions.

- Certifications: Look for FDA, UN, ISO, or other relevant certifications.

- Customer Reviews and Case Studies: See how the supplier has served clients in your industry.

- Media: Access product videos, articles, and press releases to gain deeper insight into offerings and company expertise.

Preview manufacturer websites, compare offerings, and create a shortlist of candidates capable of fulfilling your project’s requirements.

Step 4: Assess Experience, Customization, and Support

Look for manufacturers with:

-

- Industry Focus: Experience serving your sector (e.g., food packaging, pharmaceutical boxes, e-commerce shipping).

- Customization Capabilities: Ability to design and deliver boxes with special sizes, features, coatings, or printing.

- Positive Client Feedback: Consistent, recent reviews from similar businesses.

- Technical Support: Access to packaging engineers or design teams for complex projects.

Need help comparing suppliers? Try searching: “What are the best custom corrugated box manufacturers near me?”

Step 5: Request Quotes and Compare Value

Use IQSDirectory.com’s Request for Quote (RFQ) tool to contact multiple manufacturers efficiently. Provide detailed specs—box size, strength, quantity, features, and intended application—to ensure accurate quotes. Compare not only pricing, but also:

-

- Production Lead Times: How quickly can they deliver?

- Minimum Order Quantities: Do they accommodate your volume needs?

- Value-Added Services: Design consultations, inventory management, or logistics support.

Step 6: Verify Reputation, Compliance, and Support

Check for up-to-date company profiles, active news releases, and engagement in industry events via the IQS Newsroom. Reach out directly to ask about:

-

- Service Guarantees: What is their policy on defects or delivery delays?

- Regulatory Compliance: Are their products certified for your specific market?

- Ongoing Support: Do they offer design revisions or troubleshooting after purchase?

Step 7: Consider Location and Delivery Speed

Favor local suppliers when rapid delivery, in-person support, or reduced freight costs are critical. IQSDirectory.com allows you to filter manufacturers by geography to find partners in your preferred region.

Additional Tips:

-

- Explore Related Categories: Can’t find your ideal supplier? Check “Corrugated Packaging,” “Cardboard Boxes,” or “Shipping Containers.”

- Share and Connect: Use social sharing and networking features to expand your search or recommend suppliers.

- Provide Feedback: IQSDirectory.com welcomes suggestions—use the “Contact” link to request more info or report issues.

Why Choose IQSDirectory.com for Corrugated Box Sourcing?

-

- Targeted, Industry-Specific Results: Avoid irrelevant listings and find suppliers focused on industrial packaging.

- Comprehensive Profiles: Make informed decisions with detailed company information, certifications, and customer reviews.

- Patented Search Features: Website previews and streamlined RFQ tools save time and simplify supplier evaluation.

- Geographic Filtering: Quickly identify local partners to maximize speed and minimize shipping costs.

Ready to streamline your packaging supply chain? Browse top corrugated box manufacturers on IQSDirectory.com to connect with industry leaders offering custom solutions, fast delivery, and expert support.

Common Questions When Selecting Corrugated Packaging:

- What is the best corrugated box for shipping fragile items?

- How do I ensure my corrugated packaging is eco-friendly?

- Can I get custom-printed corrugated boxes with my company logo?

- What certifications should I look for in a corrugated box supplier?

- Where can I find corrugated box manufacturers near me?

For answers and expert assistance, visit IQSDirectory.com or reach out to our team today!

What are the main industrial applications of corrugated boxes?

Corrugated boxes are widely used in shipping and transportation, storage and warehousing, product protection during manufacturing, food and beverage packaging, e-commerce fulfillment, pharmaceuticals, automotive logistics, chemical handling, and electronics distribution. Their strength, customizability, and protective qualities make them essential in these sectors.

How are corrugated boxes constructed for different applications?

Corrugated boxes are made from kraft paperboard with fluted mediums sandwiched between linerboards. Depending on the application, they come in single-wall, double-wall, or triple-wall constructions. Features like moisture resistance, anti-static liners, custom dividers, and printed branding are often added to meet industry-specific needs.

What are the key benefits of using corrugated boxes in industrial settings?

Corrugated boxes provide durability, product protection, cost-effectiveness, recyclability, customization, and printability. They offer cushioning during shipping, reduce freight costs, support branding, and help businesses achieve sustainability goals.

How do I choose the right corrugated box for my products?

Selecting the right box involves considering the product’s weight and fragility, environmental exposure, required box strength (single, double, or triple-wall), regulatory compliance, any special features like custom inserts or coatings, and branding requirements. Consulting with packaging experts can help tailor solutions to your application.

What types of corrugated boxes are available?

Common types include Regular Slotted Containers (RSC), die-cut boxes, telescoping boxes, folder boxes, and fully custom boxes with specialty finishes. Corrugated boxes can be further enhanced with coatings, foam inserts, and custom printing for unique applications.

How are corrugated boxes manufactured?

Manufacturing begins with producing kraft paper from wood pulp. The paper is formed into fluted sheets and glued between linerboards on corrugator machines, then cut, slotted, and folded into boxes. Additional customization may include die-cutting, printing, and applying coatings for protection or branding.

What factors should be considered when sourcing corrugated box manufacturers?

Consider the manufacturer’s experience in your industry, customization capabilities, certifications (such as FDA, UN, ISO), minimum order quantities, lead times, customer reviews, and support services. Proximity may also matter for faster delivery and reduced shipping costs. Using platforms like IQSDirectory.com can streamline the process of finding reputable suppliers.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

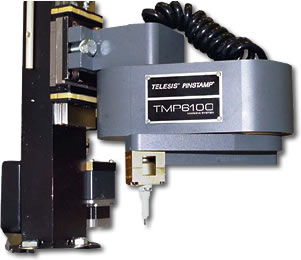

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services